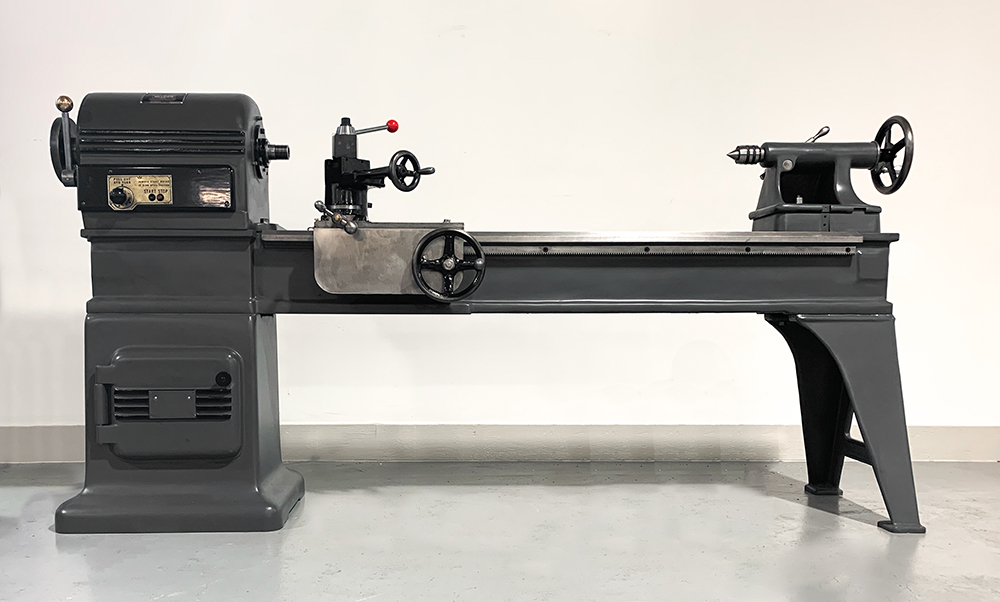

The motor’s 4 speeds were accomplished by having 4 separate windings; it is a veritable marvel of 1940’s electrical engineering. This lathe can swing a work piece 20” in diameter with almost 60” between centers, and it can accommodate a turning nearly 8’ in diameter on the outboard end of the spindle. The lathe is equipped with an original free-standing Oliver steady rest for outboard turning. It has a tool carriage with a rack and pinion feed as well. The spindle thread is a 1 7/8”-6 TPI with a 4 Morse Taper internal diameter. This lathe was last used in a piano restoration shop. The sheer magnitude of this lathe intimidates at first, but the smooth running created by its huge cast iron mass quickly endears it to the operator.

The motor’s 4 speeds were accomplished by having 4 separate windings; it is a veritable marvel of 1940’s electrical engineering.

This lathe can swing a work piece 20” in diameter with almost 60” between centers, and it can accommodate a turning nearly 8’ in diameter on the outboard end of the spindle.

The lathe is equipped with an original free-standing Oliver steady rest for outboard turning.