Turning in History

These monarchs, considered divine rulers at the time, embraced this craft as way of building their prestige and displaying their sophistication. A small group of highly skilled craftsmen taught jealously guarded techniques to the kings, and often queens, from England and France to Russia, and from Denmark and Germany to Italy, and all across Europe. Ornamental turnings were intended to reflect the magnificence of these leaders and create wonder and admiration among their subjects and peers.

‘Ornamental’ is a fraught and loaded word in some circles today, implying fussy, overly embellished decoration. About 100 years ago, the Bauhaus movement, which celebrated clean, simple lines, began to challenge the traditional design aesthetics of prior periods. This modernism and the march of time into the 21st century have overshadowed the merits of the enormously complex and sophisticated Renaissance arts developed through the 18th century in Europe. It’s time to step back and reconsider these extraordinary Renaissance crafts which were so central to our cultural evolution. In doing so, it is instructive to view the arts of the period through the lens of ornamental turning.

Ornamental turning is the process of making art objects on a rotating axis with great care and precision, using a variety of materials, shaping tools and techniques. These objects can be elegant and refined, simple and spare, baroque and elaborate, or, occasionally, bizarre, as the taste and skill of the designer and maker dictates.

Ornamentally turned objects are most often created from very dense hardwoods. During the Renaissance and into Victorian times, ivory was also a popular material; but now, of course, it is no longer used. To work these difficult materials, new and complex tools were developed. When early mariners were just beginning to use clocks to calculate longitude, the equipment and skills used in ornamental turning had already matured. The craft was using complex gears, precisely made polished steel parts, and accurately threaded screws that would only become common in industry much later. Wondrous, and previously unimaginable forms became possible because the tools became possible. The development of these tools, and their makers’ fascination with the possibilities of ever greater precision, caused ornamental turning to evolve, technologically and artistically, well in advance of the Industrial Revolution which began 100 years later. Indeed, ornamental turning was an important precursor to the industrial development that has defined our history over the last 250 years.

The stellar machine in ornamental turning’s catalog of equipment is the rose engine. A rose engine is an advanced form of lathe with a rocking headstock mounted on pivots. The headstock’s motion is controlled by a complex set of cams, called rosettes, which revolve on the lathe’s spindle. The shapes created on the rose engine are derived from the patterns cut into the rosettes. It can be used to turn and decorate both wood, and metal, and, in centuries past, ivory as well. The rose engine’s name is derived from the observation that many of the patterns created on it are reminiscent of flower petals. Early records indicate the rose engine first appeared in the early 1500’s.

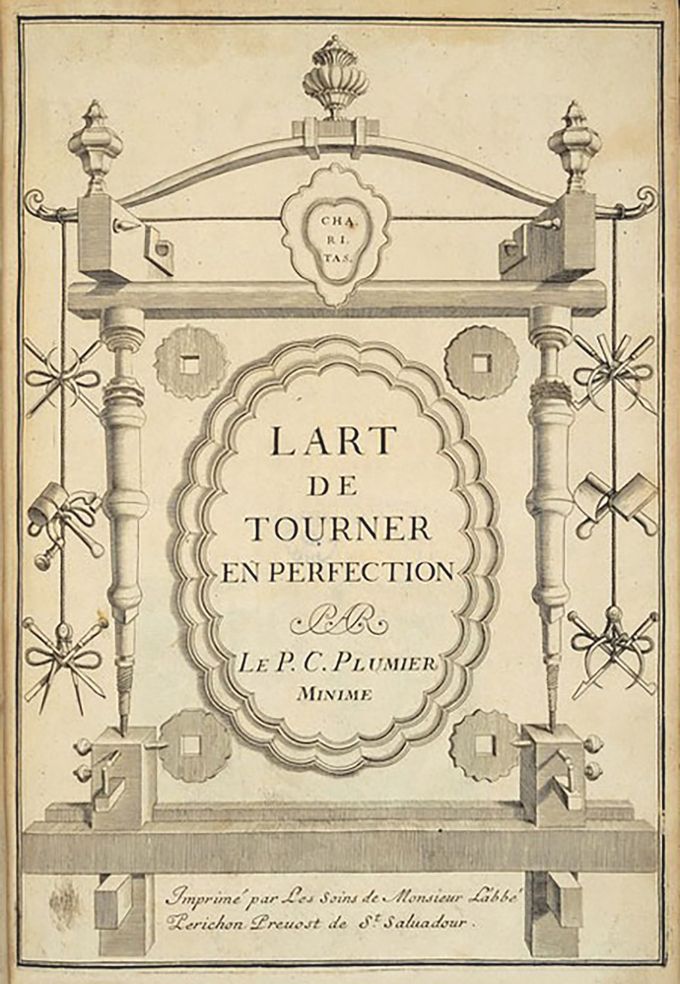

Magnificent ornamental turning objects and machines would be made for over 150 years before the world first saw a significant publication on the rose engine. At the dawn of the 18th century, Charles Plumier, a French priest, would publish his treatise, The Art of the Turner.

Plumier, a leading botanist of his time, was also an accomplished artist and engraver who learned turning from his father. Plumier’s book, whose publication was sponsored by Louis XIV of France, would stand as the only significantly useful treatise on the subject for nearly 80 years. Its significance cannot be overstated; Peter the Great had it translated into Dutch and Russian, and it spurred him to acquire as many as 50 lathes.

As the 18th century progressed toward the beginning of the Industrial Revolution, European sovereigns tried to outdo each other by creating the most beautiful machines ever made, festooning them with ornate decoration and incorporating ever more technological advancements. It is worthwhile to pause and marvel at these tools, which made unprecedented precision not just possible, but broadly achieved, at a level and accuracy not achieved in industry until almost a century later.

As the Industrial Revolution began to dawn, the rose engine’s versatility was recognized by men like Josiah Wedgwood who would apply the rose engine to his “Queensware” pieces in an effort to impress Her Majesty. With the Industrial Revolution proceeding, ornamental turning equipment would be used for glass blowing molds, in the calico textile industry, the security printing industry, and even in the production of the first self-adhesive stamp.

Left to Right: Wedgwood’s first ceramic piece using the rose engine, called “Queensware” as it was as a gift for Her Majesty. Photo credit: Victoria and Albert Museum.

Earliest known piece with guilloche and enamel dated 1750 London. Photo credit: Victoria and Albert Museum.

Imperial egg by Faberge’ showing rose engine work under enamel. Photo credit: Sotheby’s.

In the mid-18th century, use of the rose engine to decorate metal began with a form of engraving called guilloché (also called engine turning). Often the guilloché work was covered with enamel, the enamel’s rich colors enhancing the brilliant play of light on the guilloché work.

The second half of the 18th century saw guilloché work developed to its apex in the watchmaking world by Abraham Breguet who used it extensively. The pinnacle of guilloché art in jewelry making would come a century later when Carl Fabergé combined guilloché work with colored enamels to decorate everything from his famous imperial eggs to small pendants and brooches.

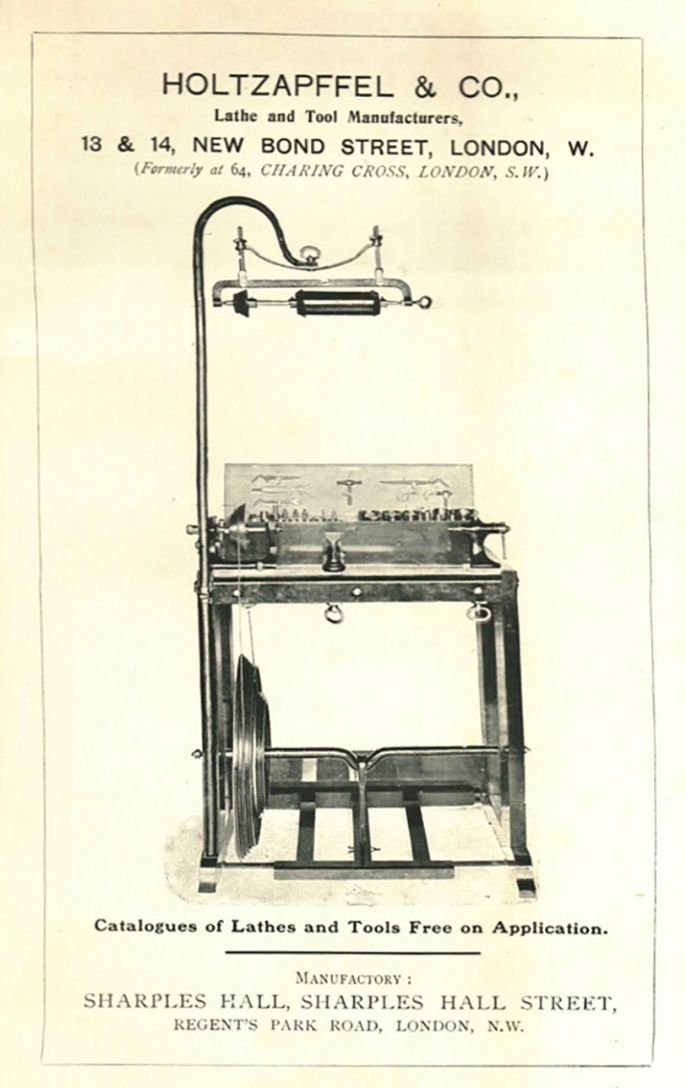

At the end of the 18th century John Holtzapffel, an Alsatian immigrant, moved to London from the Continent, and introduced commercially what would become known as the “ornamental turning lathe.” Holtzapffel simplified the astronomically expensive rocking headstock of the rose engine lathe by using a fixed headstock that could be indexed precisely. Rather than employing the rose engine’s fixed tool, the ornamental lathe used a high-speed rotating cutter to shape the work piece. This change brought the cost of these machines down to a level where a gentleman hobbyist could buy a lathe for ornamental turning, although the price of these lathes still generally restricted their use to the aristocracy. A relatively simple ornamental lathe could be purchased then for a sum equivalent to about 15 months of an average workman’s salary. Of over 2557 lathes produced by Holtzapffel & Co. during their 130-year existence, only 20 were rose engines and only 3 of those were the most elaborate type. The finest rose engine that Holtzapffel & Co. ever produced is at the Plumier Foundation.

Throughout the 19th century the ornamental turning world’s evolution would be fueled by the Industrial Revolution’s fascination with all things mechanical. Even Queen Victoria, herself a turner, would gift a Holtzapffel lathe to her cousin, Otto of Habsburg. Like the kings of centuries before, gentleman “amateurs” competed to produce ever more elaborate tools and turnings, incorporating the latest technological developments. As the 20th century dawned, the skills of the turner were being displaced by more advanced tools and equipment for industrial, military, and scientific endeavors. Holtzapffel & Co.’s creative and skilled tradesmen built highly sophisticated tools, and those tools were used to create wondrous works of art. But the Holtzapffel firm, having survived through four generations of innovation, was overtaken by technological and cultural changes and would close its doors permanently in 1927, even before the Great Depression. Computers and digital tools have come to the fore in the 21st century as they drive a large part of the art world and its creativity. The Plumier Foundation celebrates that as a continuation of what these men and women were trying to accomplish even as we preserve their stories and techniques.