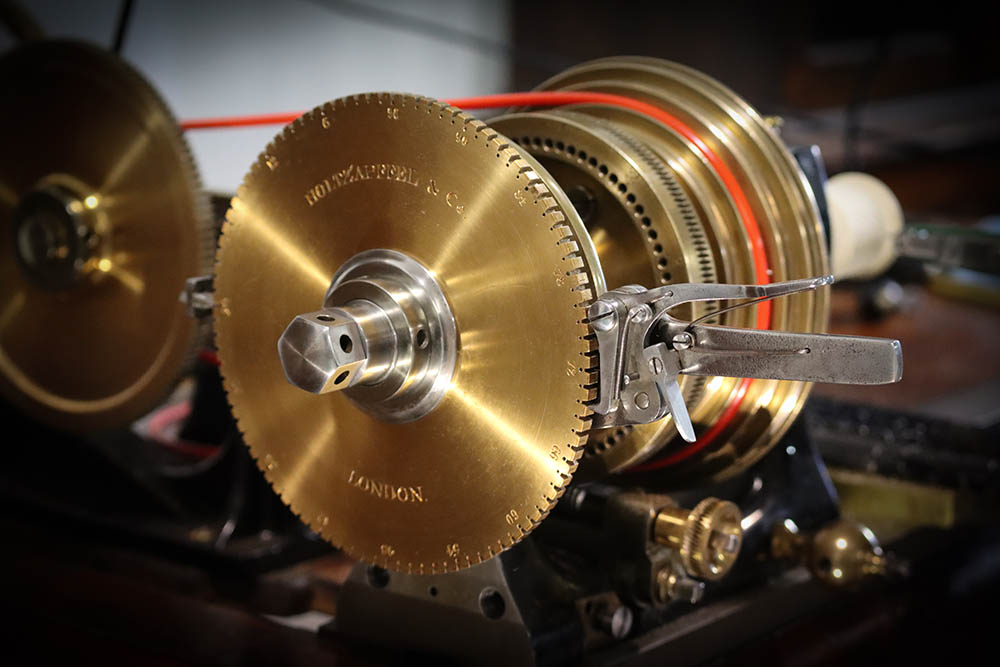

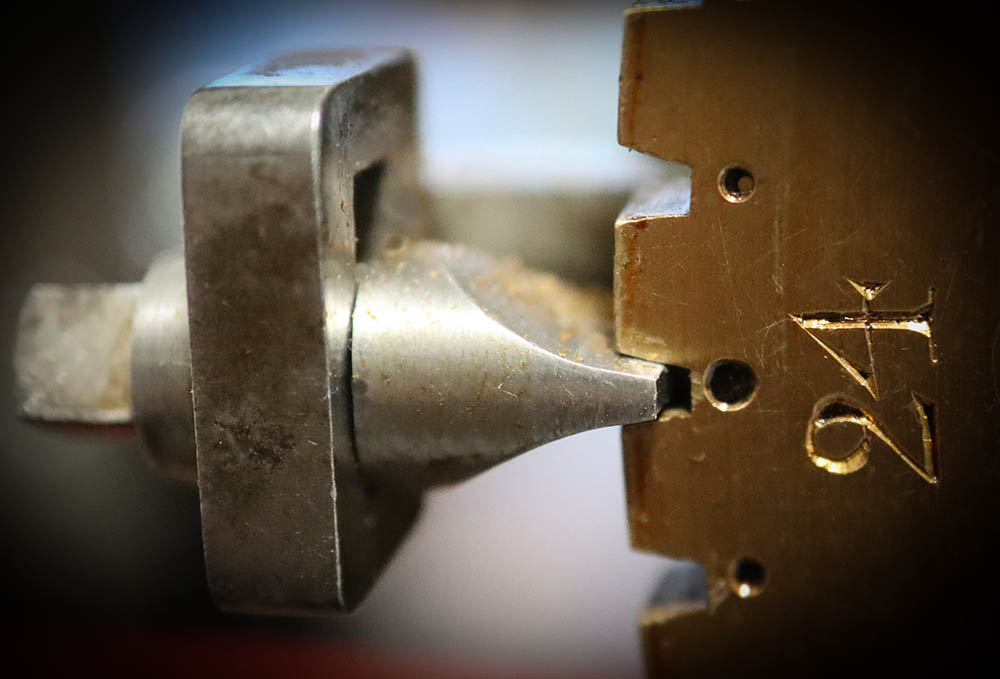

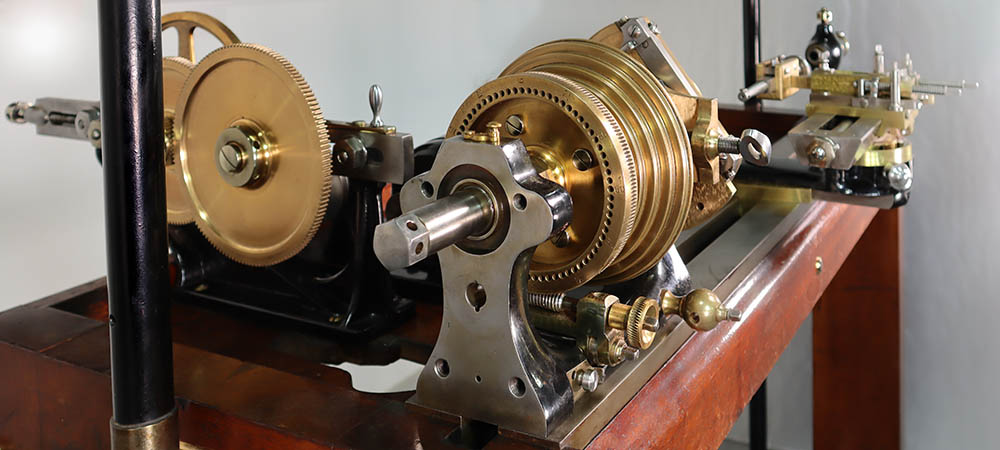

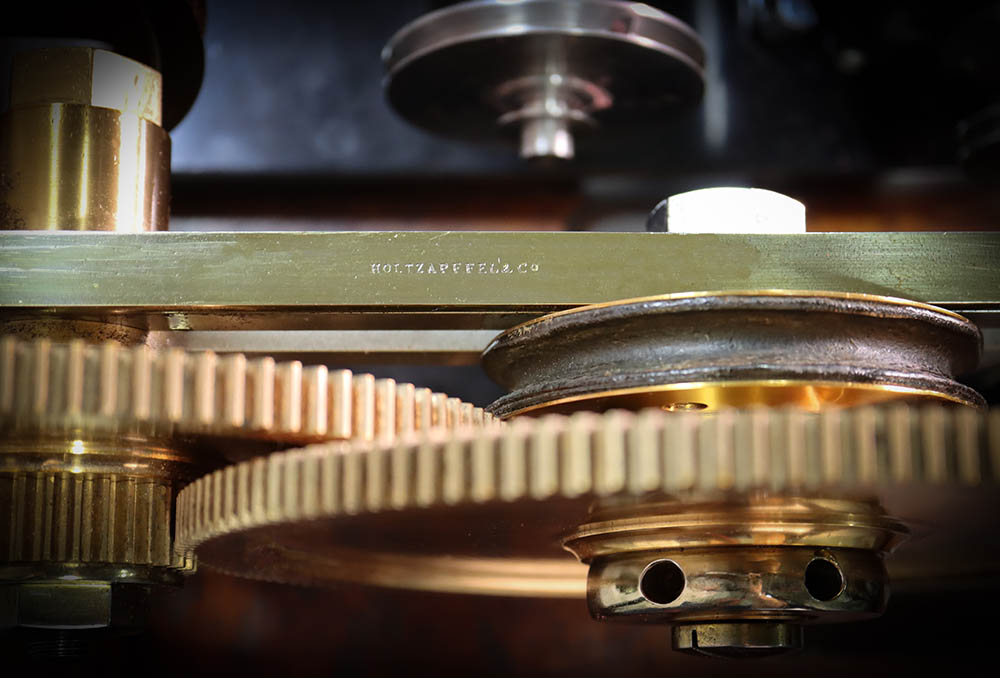

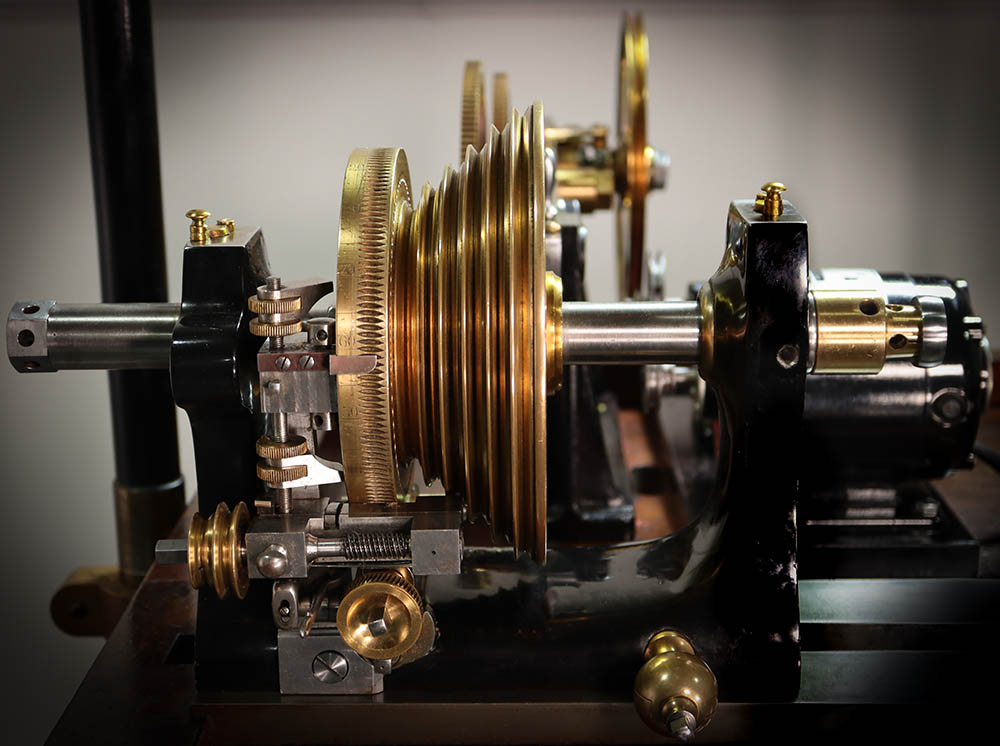

It was his second lathe purchased new from Holtzapffel, and he traded in his first lathe on the second. It is obvious that Mr. Bevan knew exactly what he wanted in upgrades, as he ordered the lathe exceptionally well equipped and requested many of the parts typically made in brass to be made of more expensive gun metal. The cost of the initial order was 670 Pounds Sterling; however, before the year was up, he would order accessories costing over 100 Pounds more, making No. 2410 perhaps the 3rd most expensive lathe Holtzapffel ever made.

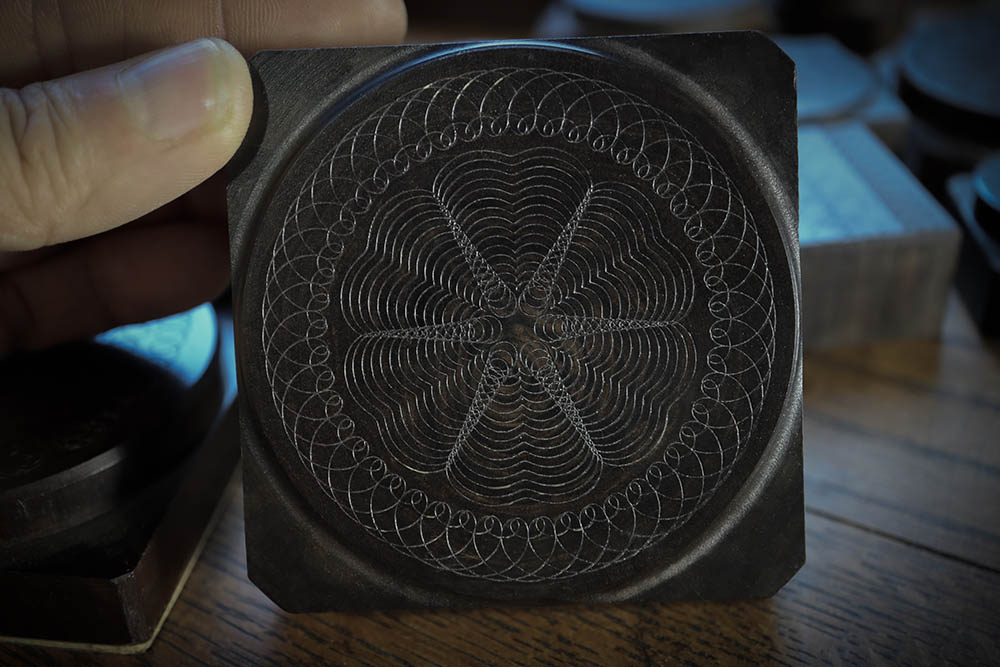

In 1907 the Holtzapffel company sold No. 2410 to William Henry Adolphus Gaddum Esq. Mr. Gaddum added to the lathe’s accessories, used it a great deal and happily left quite a record of his work. Indeed, one can spend hours looking through his pattern samples and marveling at the coded instructions he recorded for them (Unfortunately, he didn’t leave us a key to the code.). These pattern samples tell us much about both Mr. Gaddum’s abilities and his accessories. He made extensive use of both the epicycloidal cutting frame and the rectilinear chuck and employed many pumping cams as well. The patterns also tell us that he had one of Budd’s Rose Chucks and likely used another rose turning device as well. He was apparently preparing to print a book with the patterns. Happily, we have the patterns both in wood samples as well as many multiples in print. Upon his death Gaddum left the lathe to his grandson, John Walter Payne.

Mr. Payne kept the lathe until about 1960 when it was sold to Lewis Motley whose great-grandfather was the original owner of Holtzapffel rose engine #1107, purchased in 1817. Clearly the gene for good taste and mechanical prowess had survived the generations. Payne retained the lathe until his death in November, 1968.

Robert Thornton Benthall bought the lathe from the Payne estate in 1969, but, as he was elderly, only kept it until 1971 when it was purchased by Ronald Adames who reported that it was accompanied by a great many accessories as well as a number of mahogany tool cabinets and a large assortment of literature and records. The bulk these records and literature has stayed with the lathe and are the foundation of the Plumier Foundation Library and Archive.

Mr. Adames retained the lathe until his death in 1992 when it was purchased by John Edwards. By this time much of the equipment had been separated from the lathe and its whereabouts were unknown. Remarkably, and true to his nature, John Edwards was able to hunt down the majority of the original pieces and reunite them with the lathe. Equipment he didn’t find was largely replaced by similar pieces to fill out the kit as it was originally equipped, making it once again one of the most complete Holtzapffel lathes in the world. In time, John Edwards would sell this exquisite piece of equipment to Bill Ruprecht who set it in storage until the Plumier Foundation was incorporated.

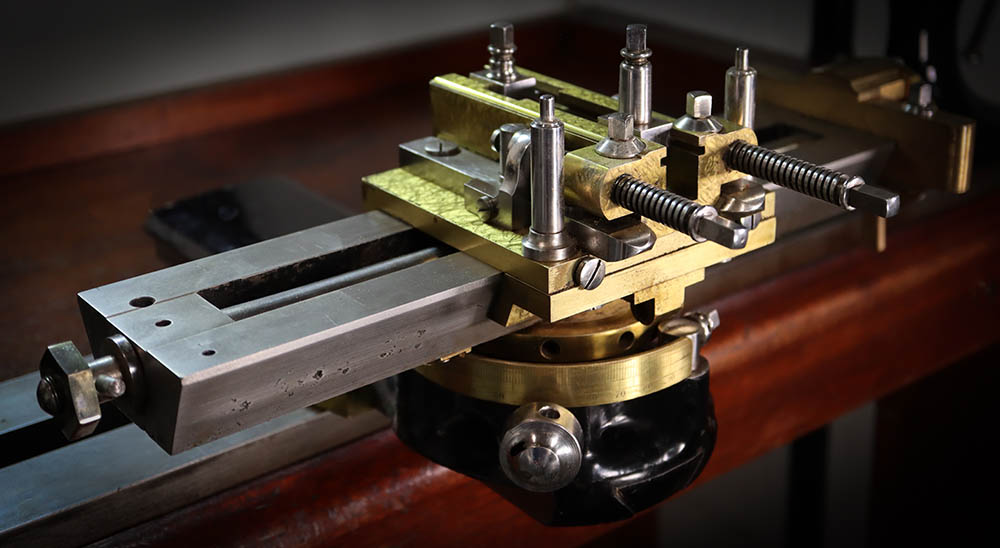

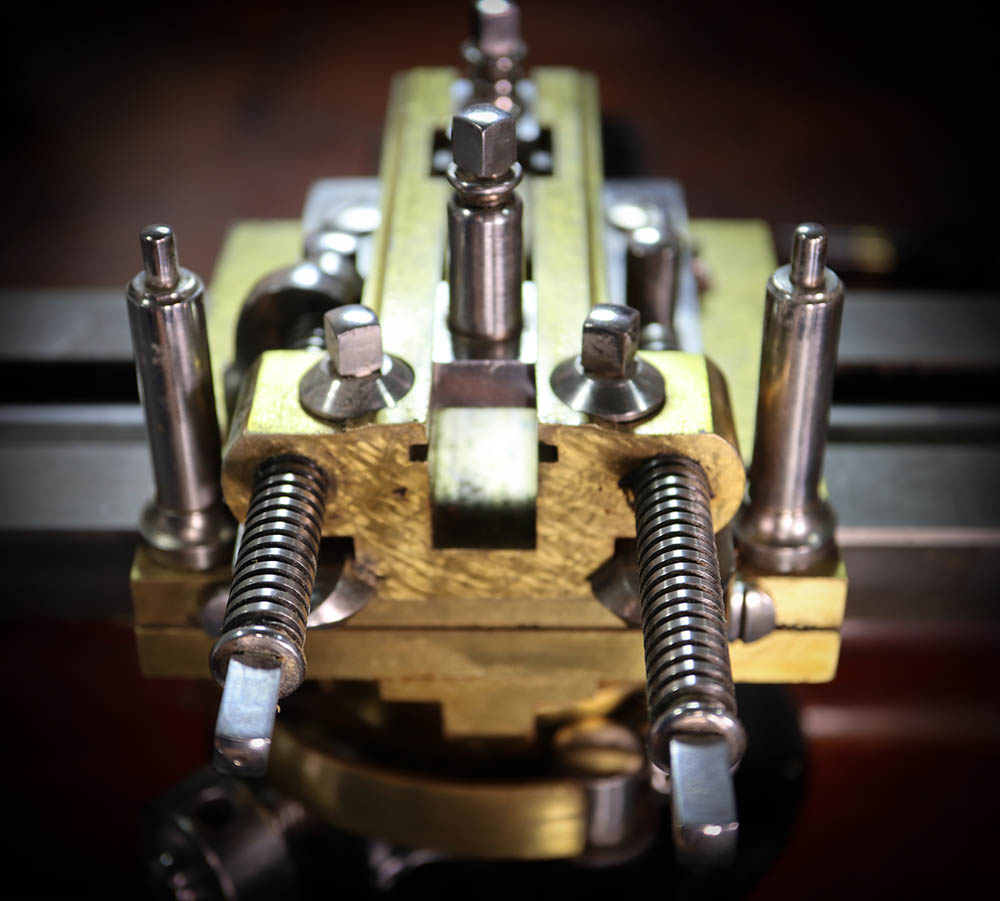

The second slow motion system is mounted on the back of mahogany stand. This drive system was originally intended to be powered via the overhead drive, but we installed a new/old stock shunt wound DC motor and jack shaft. This system is even more rare and seldom seen installed as it requires that the lathe be set out from the wall more than usual. It’s elegance in motion is exceeded only by its usefulness as it aids greatly in producing extraordinarily smooth finishes.

All ornamental turning lathes provide a palette and canvas for exploration and expression, but this lathe’s large complement of effective and useful accessories adds a good deal of efficiency to the process as well.