He had paid 65 Pounds Sterling for each of his previous two lathes, but No. 2157 alone would cost 600 Pounds, making it one of the most expensive and extensively tooled ornamental turning lathes Holtzapffel & Co. produced. Unfortunately, Sir Alfred died just two years later in 1866. No. 2157 was returned to Holtzapffel & Co., then resold to George Robert Stephenson in 1868 for 425 Pounds. Stephenson owned 5 other Holtzapffel lathes.

The next known owner of the lathe was Robert Williamson who bought the lathe in 1909. Williamson’s son, Ian, would inherit the lathe after his father’s death in 1941. Ian Williamson recollected spending hours treadling the lathe for his father in those early days. He also recollected his father turning with his good friend and fellow Holtzapffel lathe owner, Lord Kelvin.

Ian Williamson inherited the lathe during war time and pressed the lathe into service for the war effort. The following is an excerpt from a letter he submitted to the Society of Ornamental Turners Bulletin

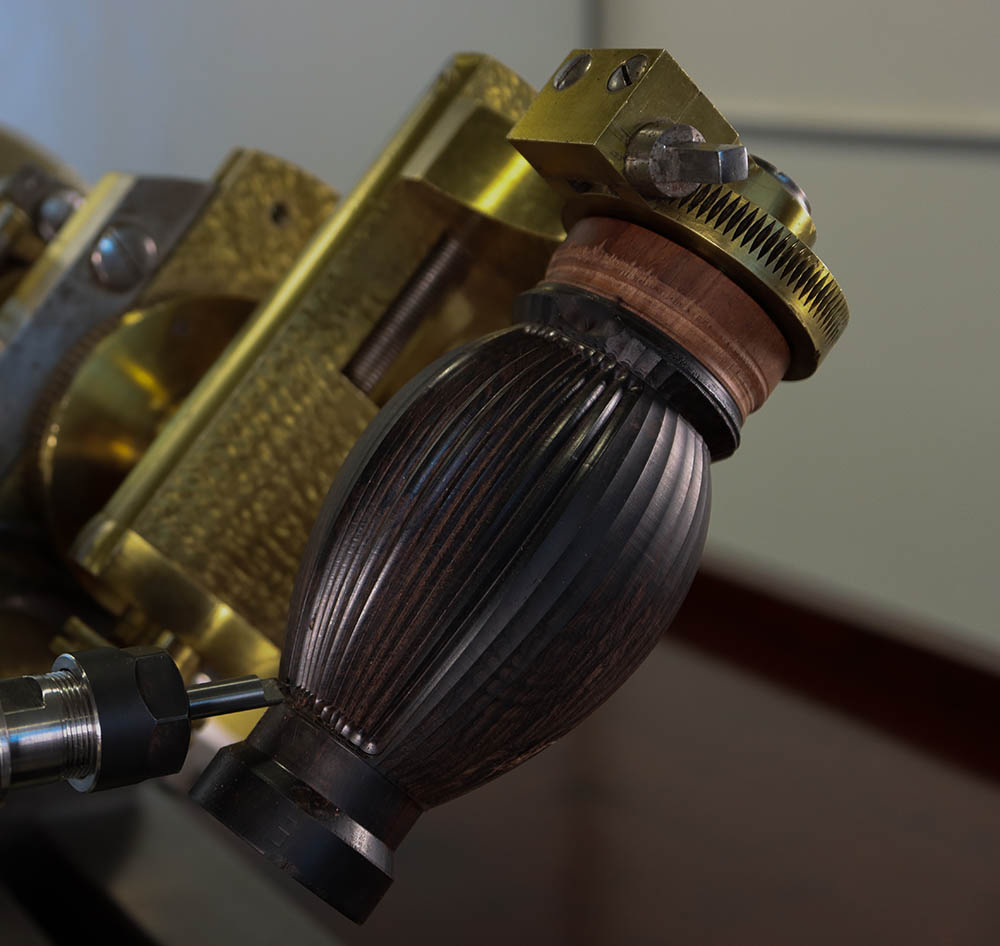

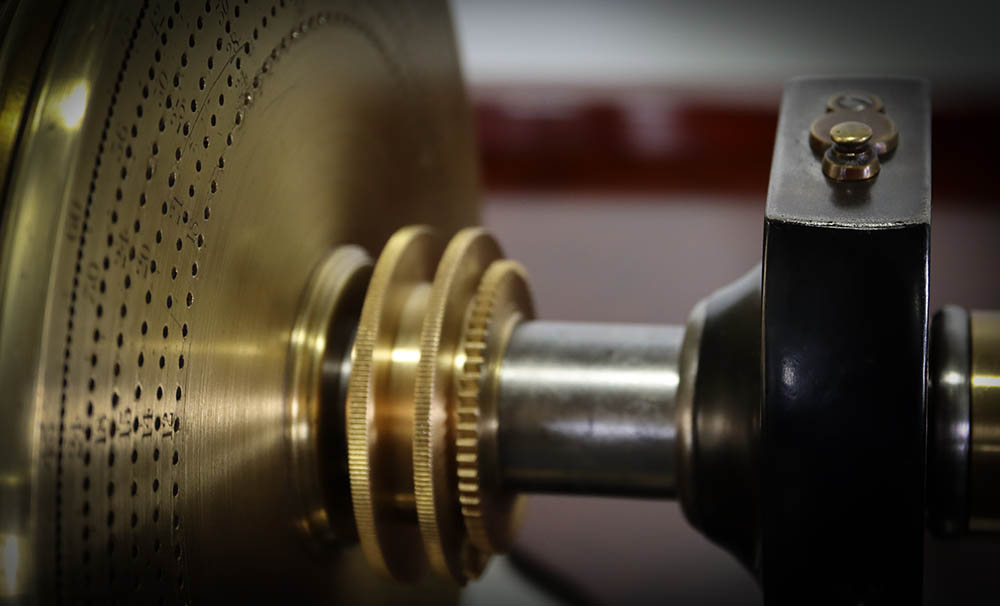

“During the last war I moved the lathe to my engineering works in Motherwell and put it to work turning out variable pitch tapered bronze swirlers for the breech blocks of 18” and 21” torpedo engines after my foreman had told me it was impossible to turn the swirlers in a lathe, A young lassie by following my instructions (including oiling) turned out hundreds of swirlers without damage to the lathe, due to her fine touch. Another job I gave her was cutting 360 radial teeth on 7” diameter adjustable cams for a ship-owner who had unfortunately equipped his ships with German pumps. For this purpose I converted the toolholder on the slide-rest into a horizontal nibbler reciprocated by a cam on the back of the tool-holder.”

Ian died in 1979 and the lathe was passed on to his son-in-law, Donald B. Briggs, of Scotland. Briggs sold the lathe to John Edwards in 2005. In 2008, Fred Armbruster purchased the lathe, brought it to America, and did a good bit of restoration to it. Bill purchased it in 2014 for what was to become the Plumier Foundation.

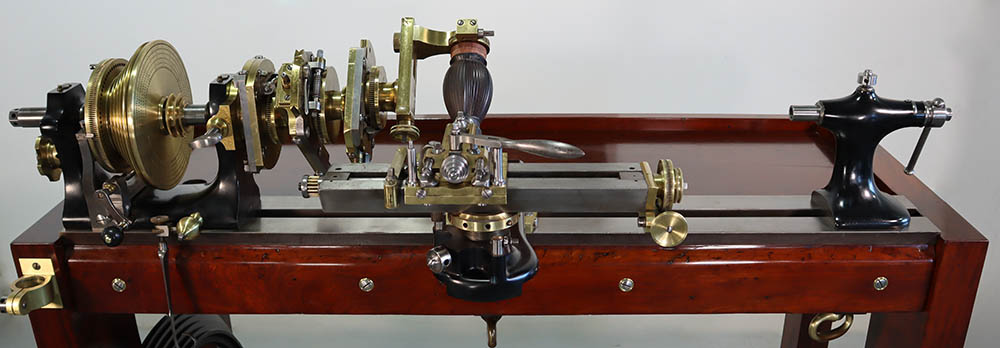

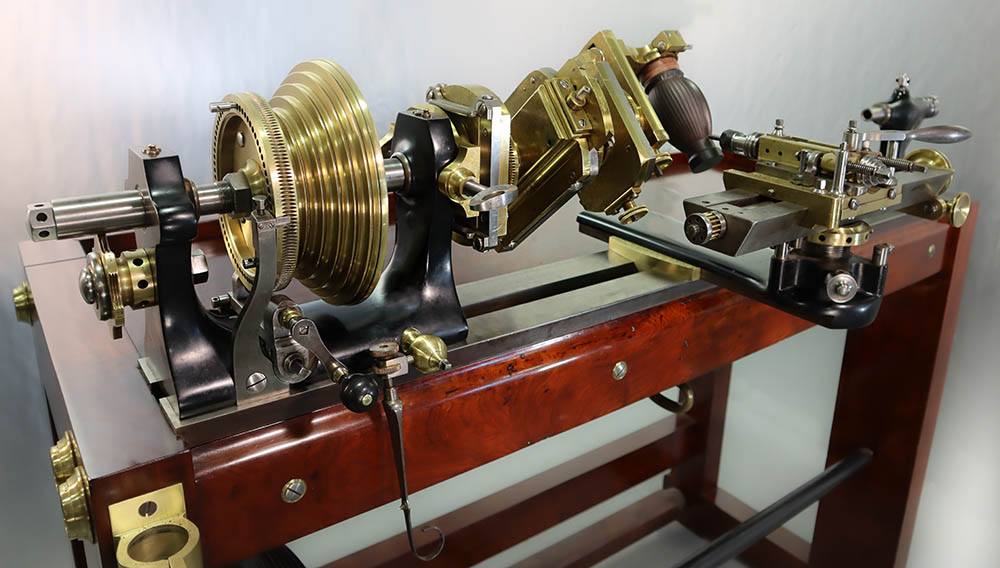

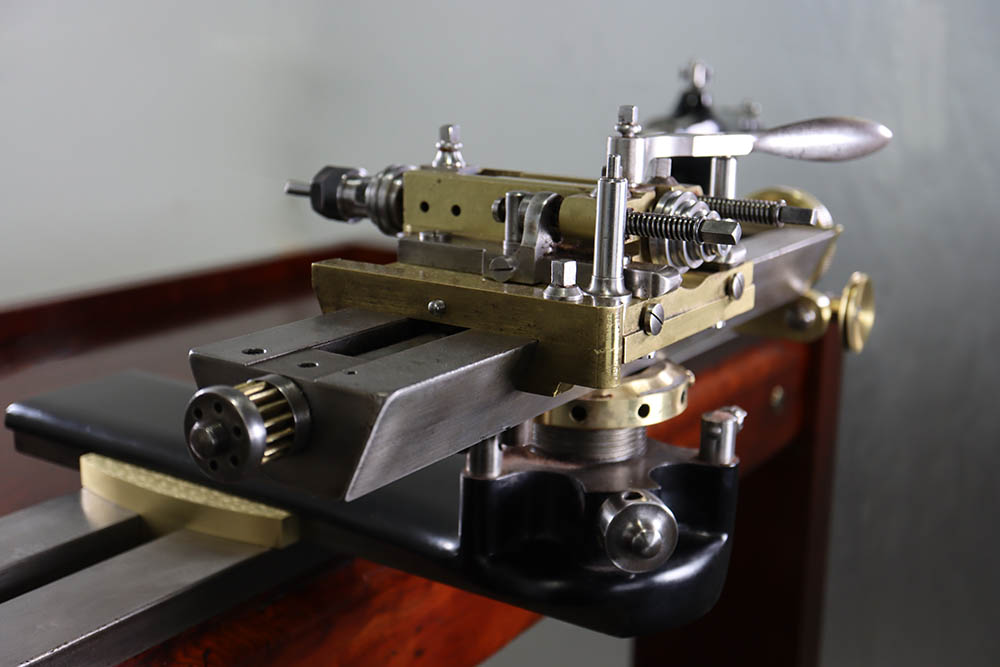

Holtzapffel No. 2157 is a “6 inch screw mandrel lathe,” the largest of the ornamental turning lathes at the Plumier Foundation. Its heavier timbers, longer and wider bed, and more massive headstock, creating an imposing presence. And yet, it is not at all ponderous, retaining the same elegance associated with all things Holtzapffel. Its original Holtzapffel tool cabinet is built on the same larger scale, but remains graceful nevertheless. A quick inspection of the cabinet quickly makes clear why this machine was among the most expensive Holtzapffel & Co. produced. There is a profusion of tooling. The cabinet includes a spiral apparatus with a face spiral, rectilinear chuck, eccentric chuck, elliptical chuck, and spherical chuck—all larger than standard to match the lathe’s greater size. The elliptical cutting frame has its own section of the cabinet and is surrounded by many other cutting frames including an eccentric cutting frame. The holding chucks are nested nicely, all having their own specific spot on the shelf, as do the measuring instruments and squares. Gears, spanner wrenches, stops, and curvilinear patterns all rest in their custom-contoured recesses. Tool rests and other heavy objects are in fitted drawers, and a set of turning chisels is neatly arrayed in the base cabinet drawers.