This simple tool, a composition of steel and brass and gleaming black horn, was a masterpiece of Victorian workmanship. The elegant horn handle presented a symphony in elliptical curves that caressed the hand and delighted the eye. More than a century has gone by since such artistic accomplishment, once commonly seen, has been present in the mechanical trades. Even after a lifetime of handling machines and tools of the highest quality, the man stood with a large grin and marveled at the beauty.

It was his second lathe purchased new from Holtzapffel, and he traded in his first lathe on the second. It is obvious that Mr. Bevan knew exactly what he wanted in upgrades, as he ordered the lathe exceptionally well equipped and requested many of the parts typically made in brass to be made of more expensive gun metal. The cost of the initial order was 670 Pounds Sterling; however, before the year was up, he would order accessories costing over 100 Pounds more, making No. 2410 perhaps the 3rd most expensive lathe Holtzapffel ever made.

In 1907 the Holtzapffel company sold No. 2410 to William Henry Adolphus Gaddum Esq. Mr. Gaddum added to the lathe’s accessories, used it a great deal and happily left quite a record of his work. Indeed, one can spend hours looking through his pattern samples and marveling at the coded instructions he recorded for them (Unfortunately, he didn’t leave us a key to the code.). These pattern samples tell us much about both Mr. Gaddum’s abilities and his accessories. He made extensive use of both the epicycloidal cutting frame and the rectilinear chuck and employed many pumping cams as well. The patterns also tell us that he had one of Budd’s Rose Chucks and likely used another rose turning device as well. He was apparently preparing to print a book with the patterns. Happily, we have the patterns both in wood samples as well as many multiples in print. Upon his death Gaddum left the lathe to his grandson, John Walter Payne.

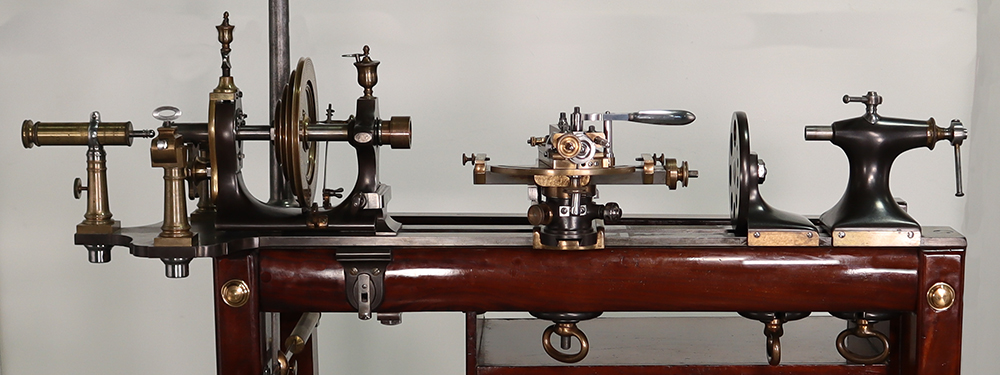

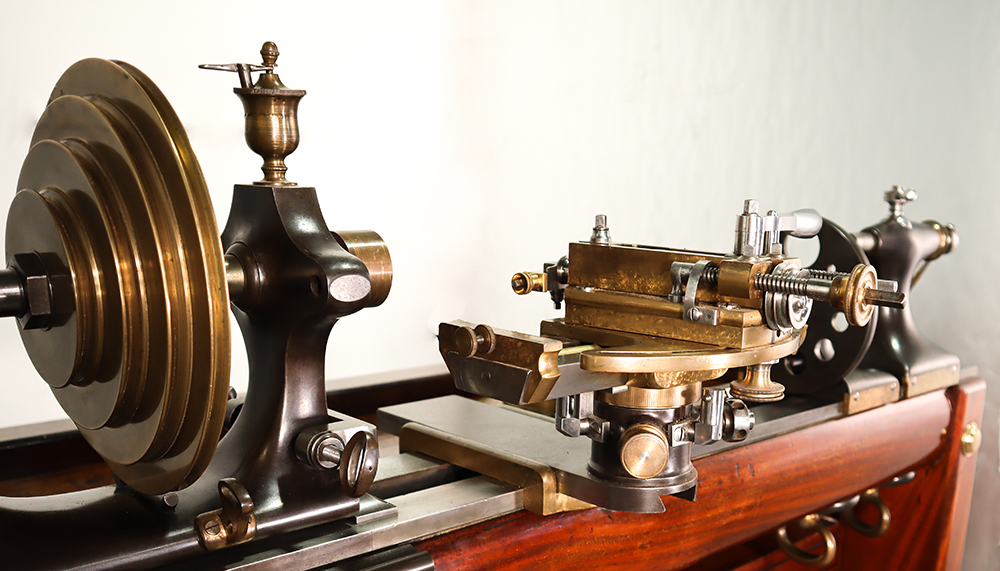

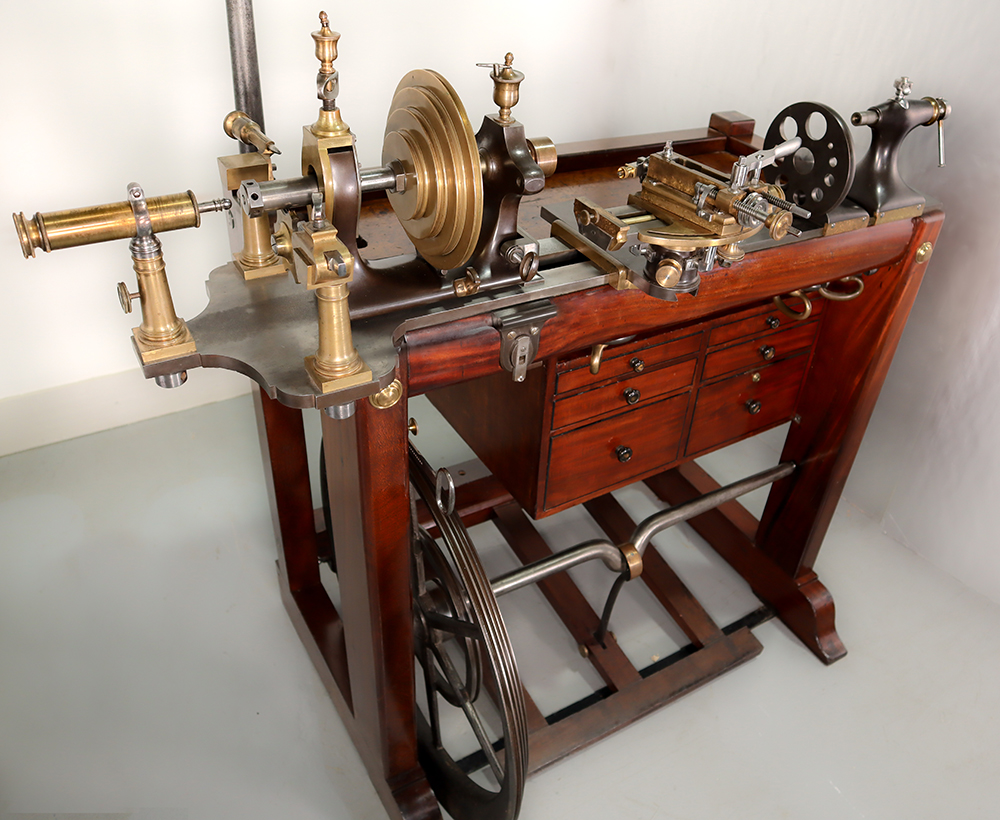

The Bower lathe is rich in accessories and has a carrier for a single rosette which mounts on the outboard end of the headstock spindle. The lathe is capable of both pumping and rocking, but the rocking feature can be locked out to use the machine as an ornamental turning lathe. Multiple versions of universal, eccentric, and drilling frames are provided, and the slide rest has interchangeable chariots including one for guilloché. It has two eccentric chucks and an elliptical chuck along with a straight line chuck on which you can mount a “pillar fluting chuck,” often called a pen chuck. The lathe also retains its original threading system which works on the traversing mandrel concept. An Evans spherical slide rest came with the lathe, but was not original to it.

The date of manufacture is unknown. John Thomas Bower was born in Scotland in 1795 or 1796 and died in 1849. His prowess in machine tool building and reconditioning was of such magnitude that the Holtzapffel firm would hire him from time to time to do modifications and work to their lathes. He is known to have converted several Holtzapffel ornamental turning lathes into rose engines.