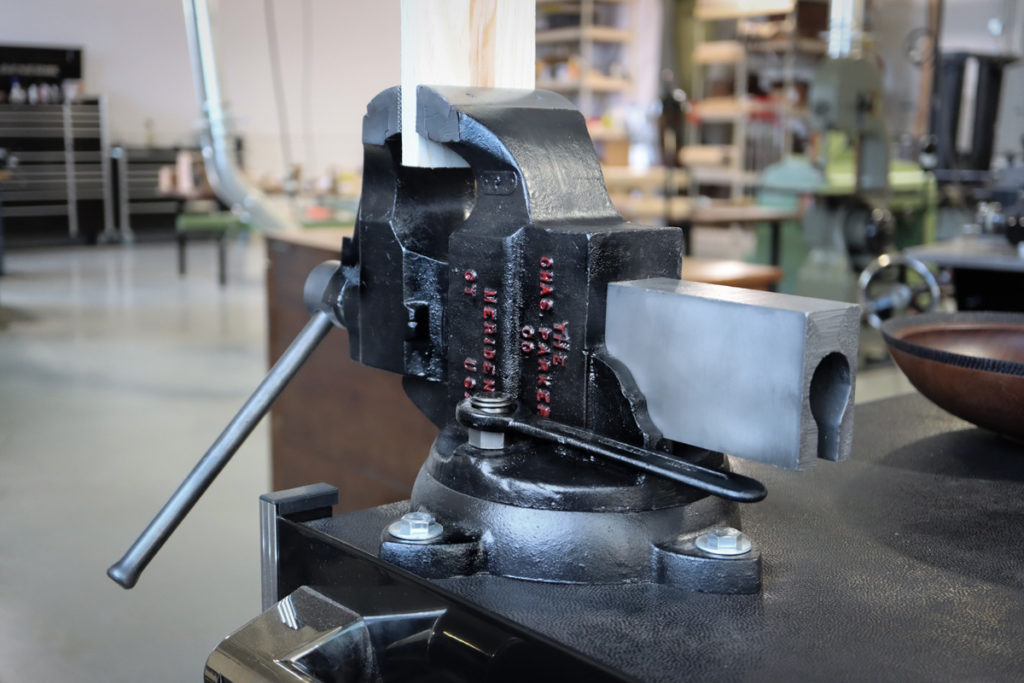

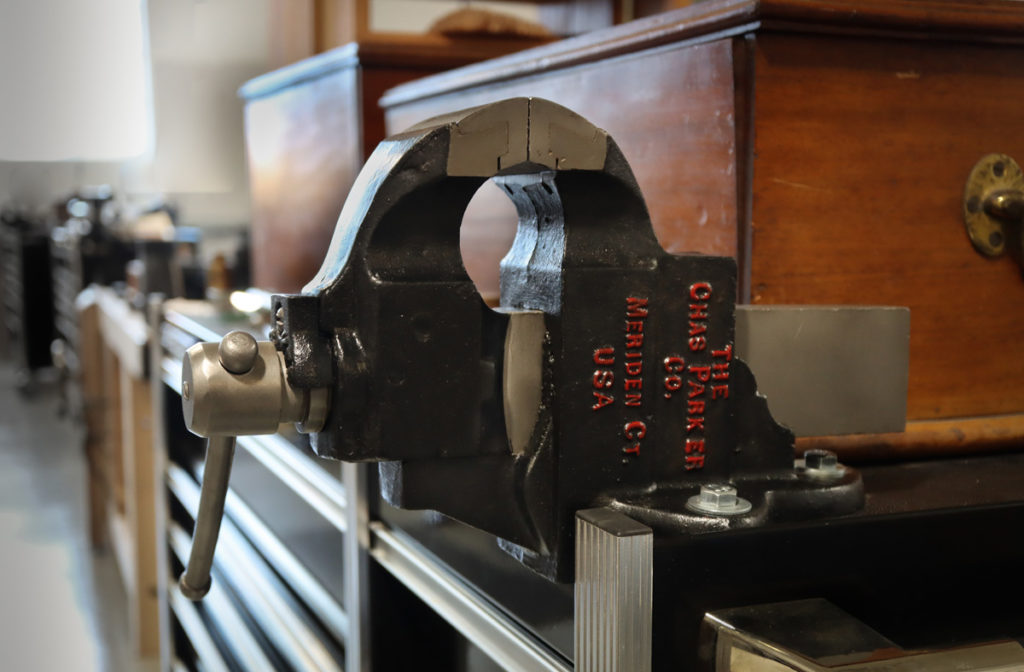

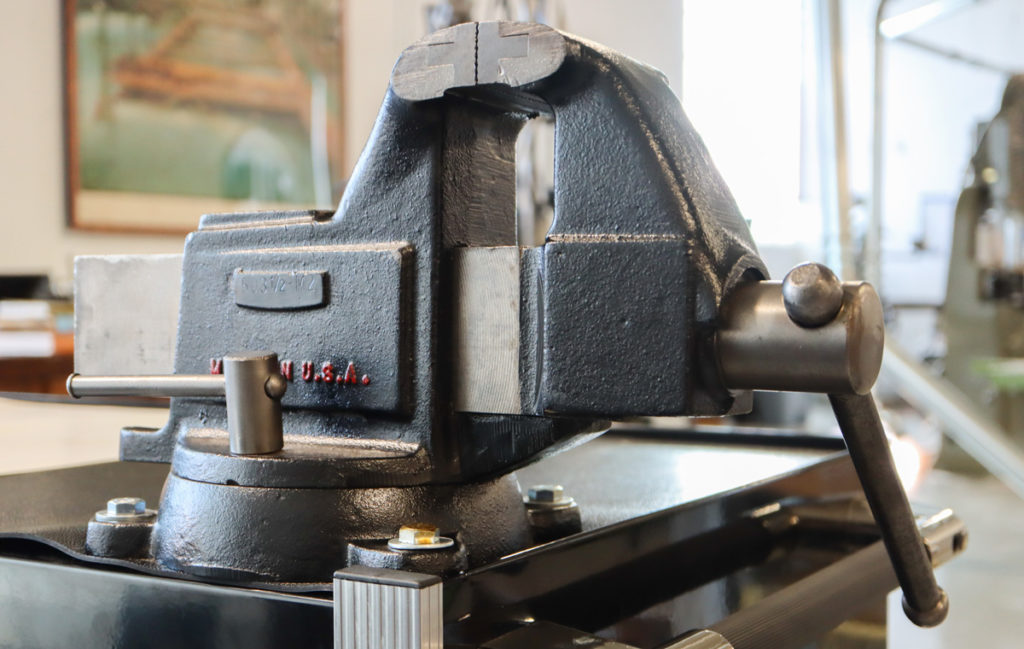

When we began to set up the shop, decisions had to be made about toolboxes, benches, etc. With all the choices in front of us and one chance to get it right, we, of course, turned to Frank Dorion for a voice of wisdom. As always, his guidance, spot on and backed up with a lot of experience, clearly set out the pros and cons of the different choices available to us. In the midst of unpacking and assembling the toolboxes and tooling benches, he suggested that we install a vise at every workstation. He didn’t stop there, however; he generously volunteered to procure the vises and restore them. In the end, he delivered six vintage vises that were sympathetically restored, looking good enough for a palace yet retaining their vintage character.

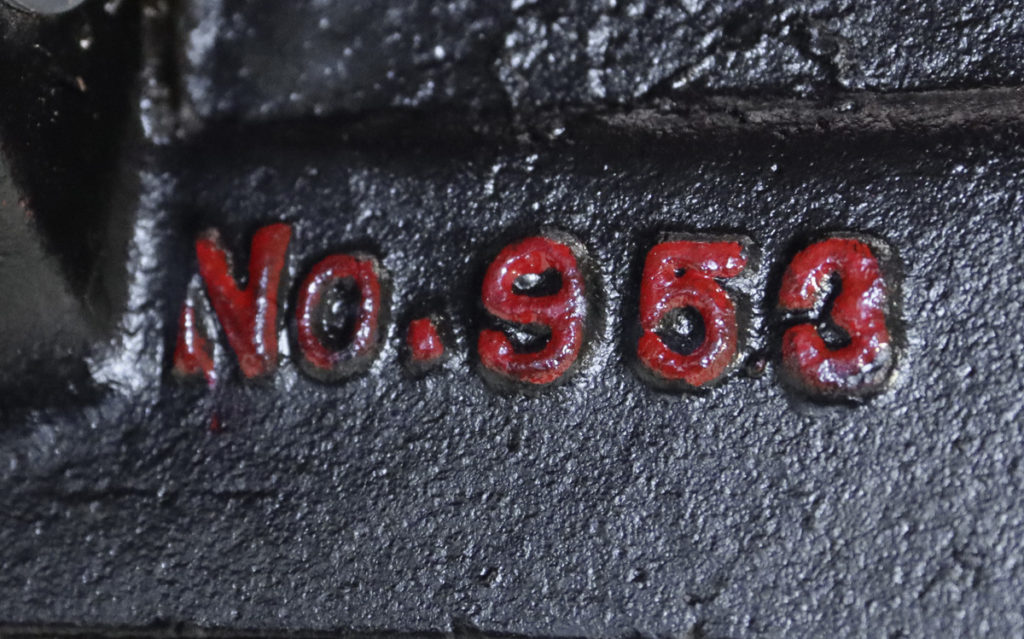

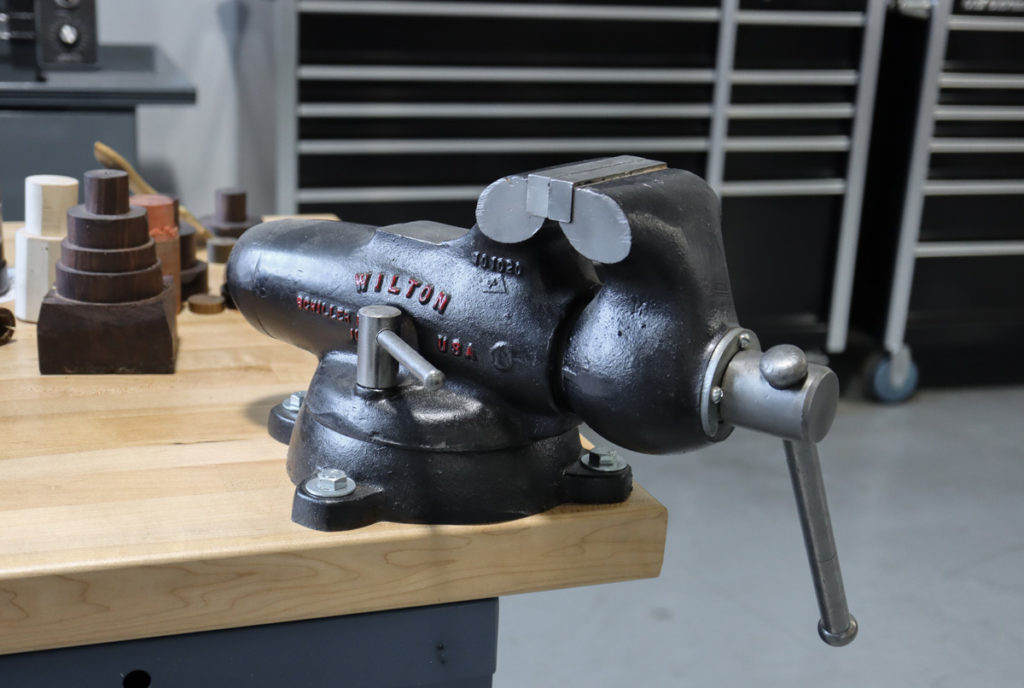

Knowing what to look for is half the battle in matters like this, and Frank was right on top of things in this regard. His choices were 4 Charles Parker vises and one each by Columbian and Wilton—all companies which are still in business in one form or another.

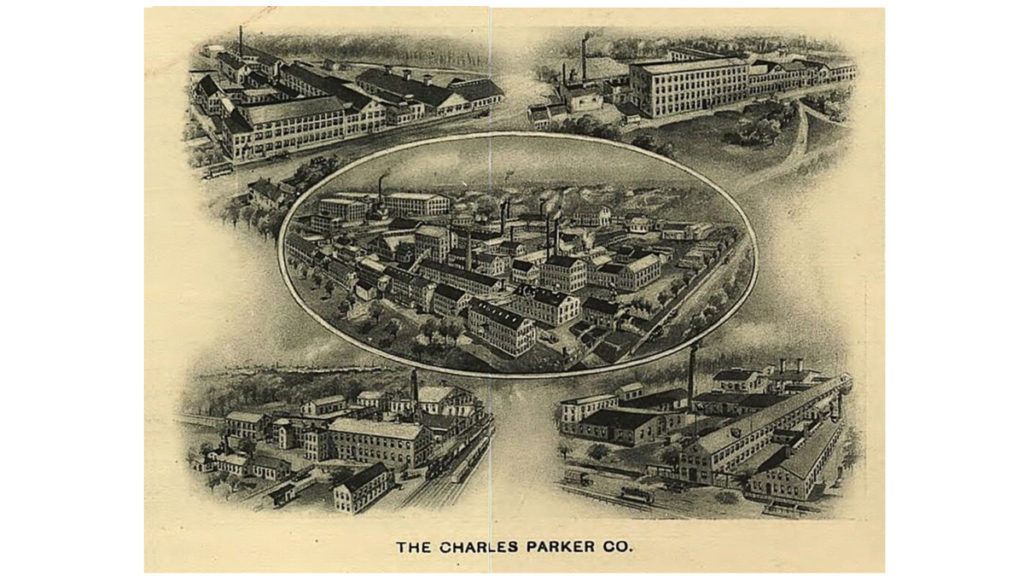

Charles Parker began his manufacturing activities in 1832 in Meriden, CT. These endeavors would eventually be spread across quite a number of companies and would include not only vises, but also art brasses, piano stools, eyewear, curtain fixtures, metal wares, lamps, and even clocks, not to mention shotguns. By 1868, Charles Parker Company had grown to fill four locations with these diversified interests, and the largest facility had buildings that covered over 2 acres. It’s the art brass company that survives today.

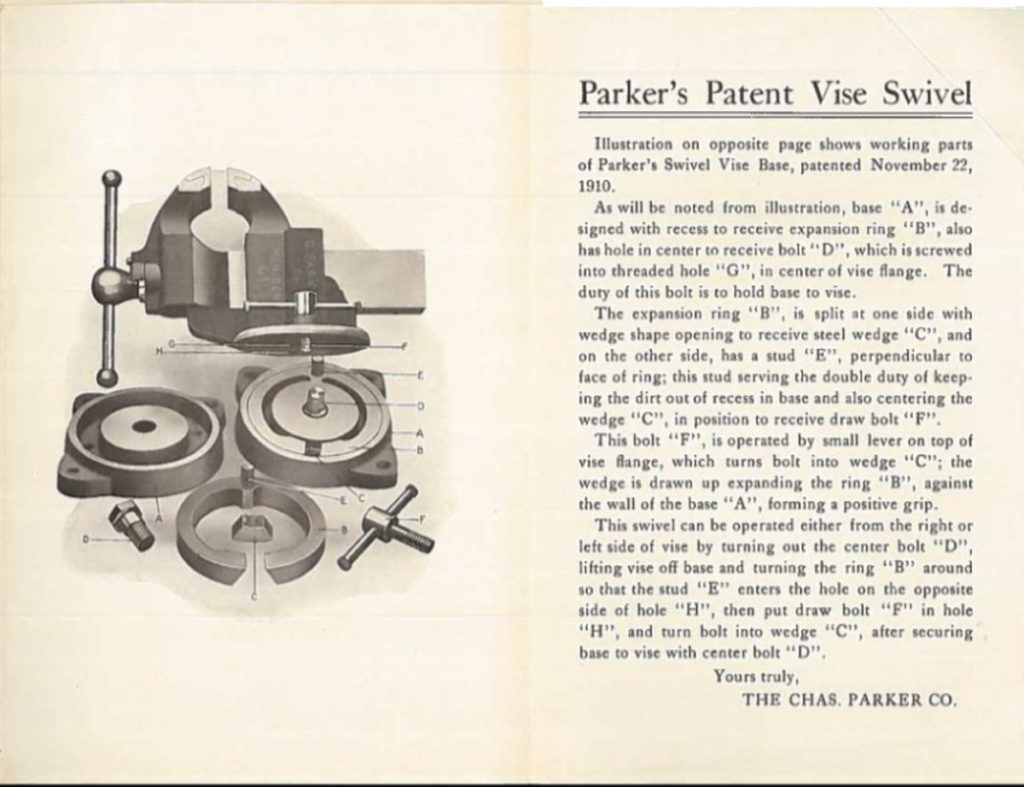

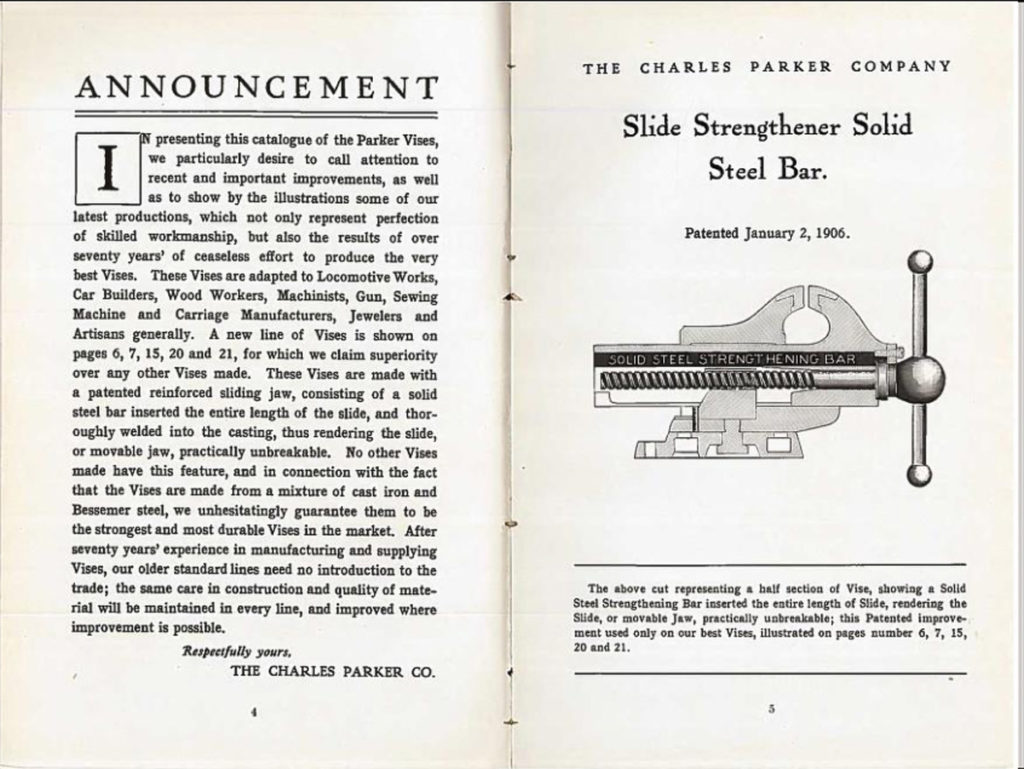

Charles Parker Company made vises into the 1970’s. Two of their best innovations were a semi-steel casting with some models carrying a piece of steel as a sort of backbone that reinforced the vise, and their patented locking mechanism for the swivel. They also made their vise jaws with curved tops, a superior design that provides better access to the work piece for filing, cold chisel cutting and other bench work.

[On a side note, it should be pointed out that the “Charles Parker” Company has no relationship to “Charlie Parker” of saxophone fame, aka “Bird.” David’s previous reference to Plumier’s vises as “Bird Vises” is erroneous and should be ignored if at all possible.]

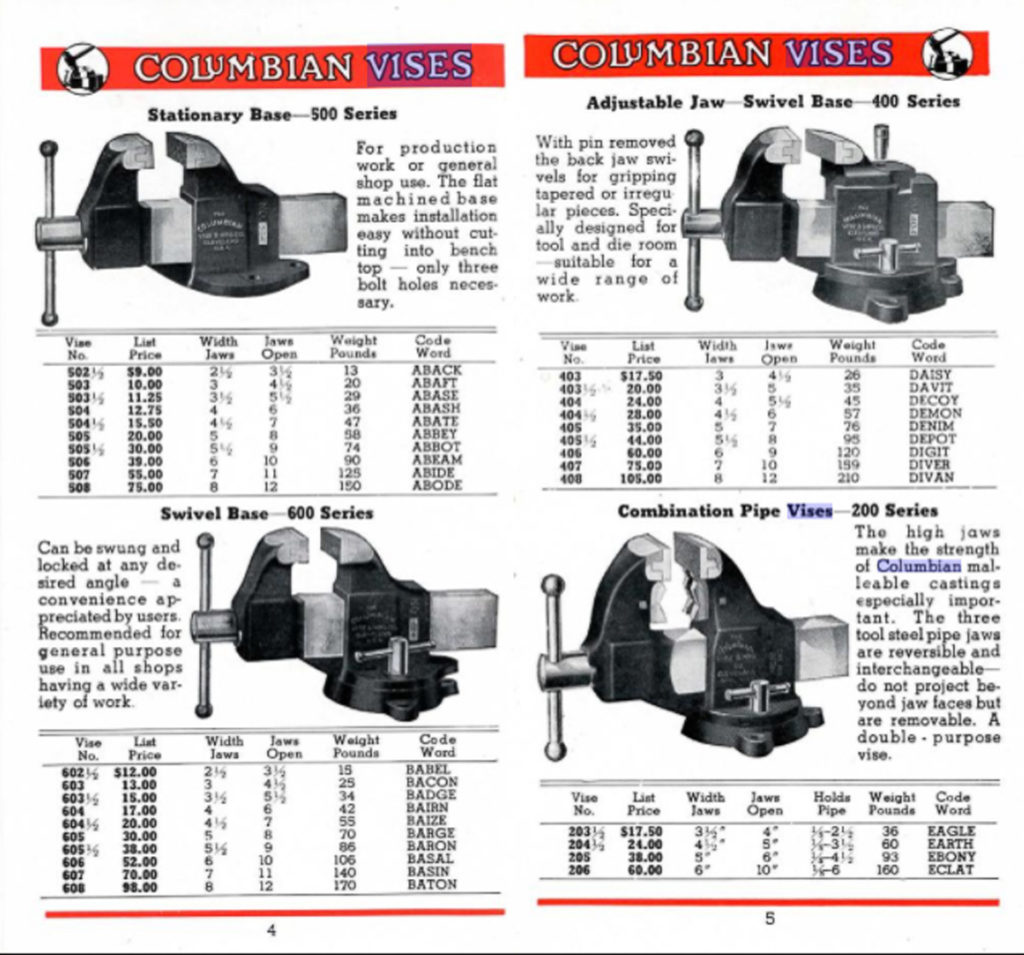

One of our vises was made by the Columbian Vise and Manufacturing Co. It’s probable that this company was formed as an outgrowth of Van Wagoner and Williams Hardware Company that owned the Trenton Vise and Tools Works. The company made vises in Cleveland, OH. Columbian made a very wide variety of vises including post vises and woodworking vises as well as anvils and clamps.

Even though they didn’t make any particularly notable innovations in vise design, Columbian made vises of exceptional quality. In time, the company would be absorbed into Wilton Tool Manufacturing whose vise manufacturing facility bore the name “Columbian” as of 2019.

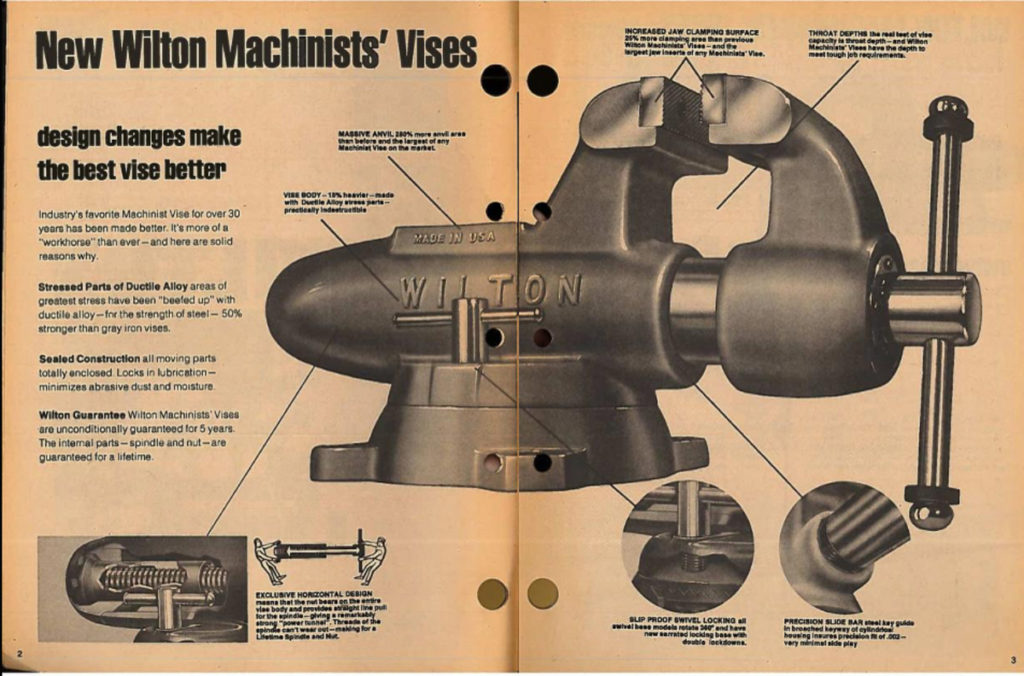

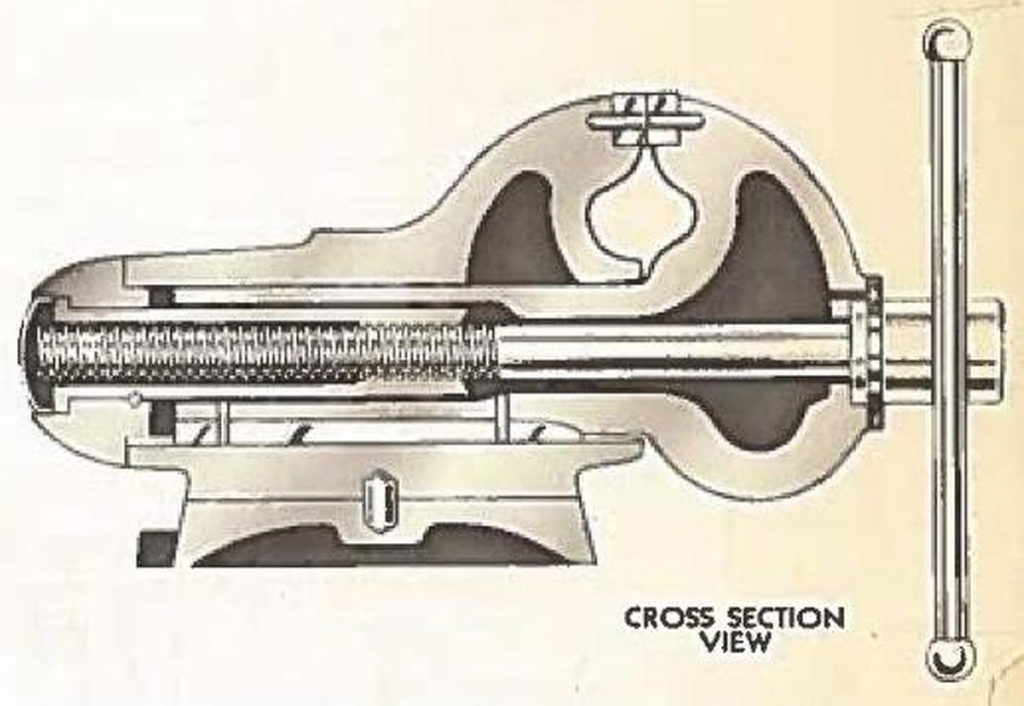

The Wilton Tool Corporation was started in 1941 by Hugh W. Vogl who named it Wilton as it was originally at the intersection of Wrightwood and Wilton Avenues in Chicago. Vogl’s innovative contribution to the vise world was in his patented “Bullet” shape. This design increased the strength of the lead screw and kept it protected from shavings and debris. The round ram was guided by a keyway that held a tolerance of .002”, less than the diameter of a human hair.

In the war years he made vises exclusively for the government, and after the war when the government dumped surplus into the open market, the company barely survived. Their biggest problem was that of distribution, and Vogl’s son, Alex, entered the company and did much to address that issue. In the early 1960’s Wilton began to manufacture wood working equipment, and even today the company is part of a conglomerate that makes all sorts of wood and metal cutting tools.

In time, Wilton would acquire the Columbian vise company, and Wilton’s current vise manufacturing facility still bears the name “Columbian.”

The vises at Plumier are used daily. Their selection and placement stand a constant reminder that without the support of friends and volunteers, organizations like The Plumier Foundation could not exist. Many thanks to Frank for helping to make all of this happen. We couldn’t be what we are without you.