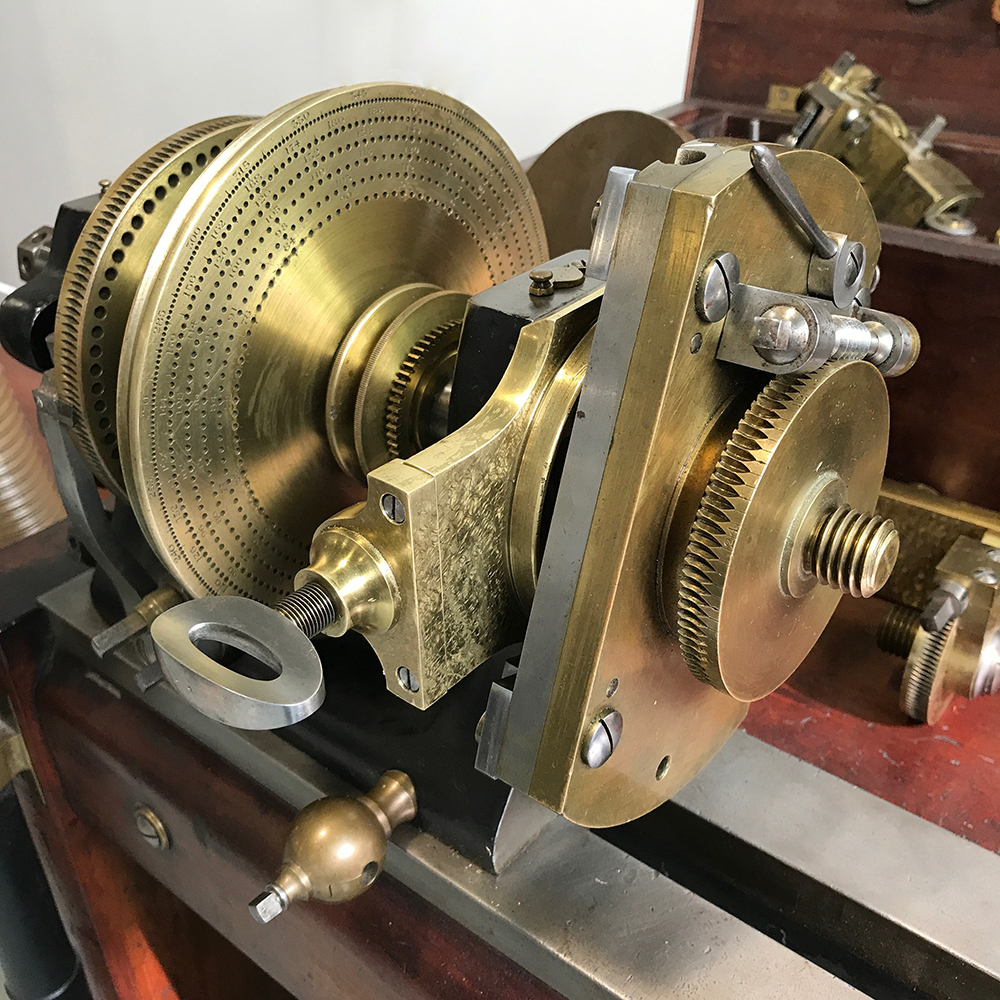

Over the years, parts of old machines get lost or broken and are often replaced. Holtzapffel lathes are no exception. Also, through the years some lathes were scrapped, but their parts were saved and used for other lathes. Holtzapffel No. 2195 was no exception; and, having been made in 1865, it’s no surprise that some of its major parts were replaced. Its oval chuck is a case in point. Before even trying to install the oval chuck and its cam ring, it was obvious that the two did not start life together. The cam ring was considerably smaller than the minimum adjustment of the pallets, the parts that follow the cam ring.

Most Holtzapffel chucks and many of their accessories were numbered to match the machine; some were not. In this case, the chuck itself was marked with the number 2195. However, the cam ring was not marked, so it was obvious that the chuck was original while the cam ring was from a different lathe.

The chances of ever mating the original cam ring with the original chuck are next to none, so it was decided that the best approach would be to make new pallets which would extend farther in to match the cam ring but bolt up exactly the same. This way, the original pallets could be retained with the lathe in hope that, against the odds, the original cam ring would one day reappear. Steel alloy 12L14 was chosen due not only to its free machining properties but because of its lubricity as well. An appropriately sized piece of square bar was obtained, and the new pallets were machined.

Once the pallets were replaced the adjustment screws had to be addressed. Three of the four were not original, and none of the threads were the original pitch. The original screws were also smaller in size so returning the threads back to the original sizes would require letting in new material, which would then require that the chuck be refinished. It was decided that retaining the original finish and present patina was more important than having the screws returned to their original pitch. Instead, new screws were made to fit the bastardized pitches but with heads that matched the original. That way, from the outside the chuck looks as it should and will function as it was intended.

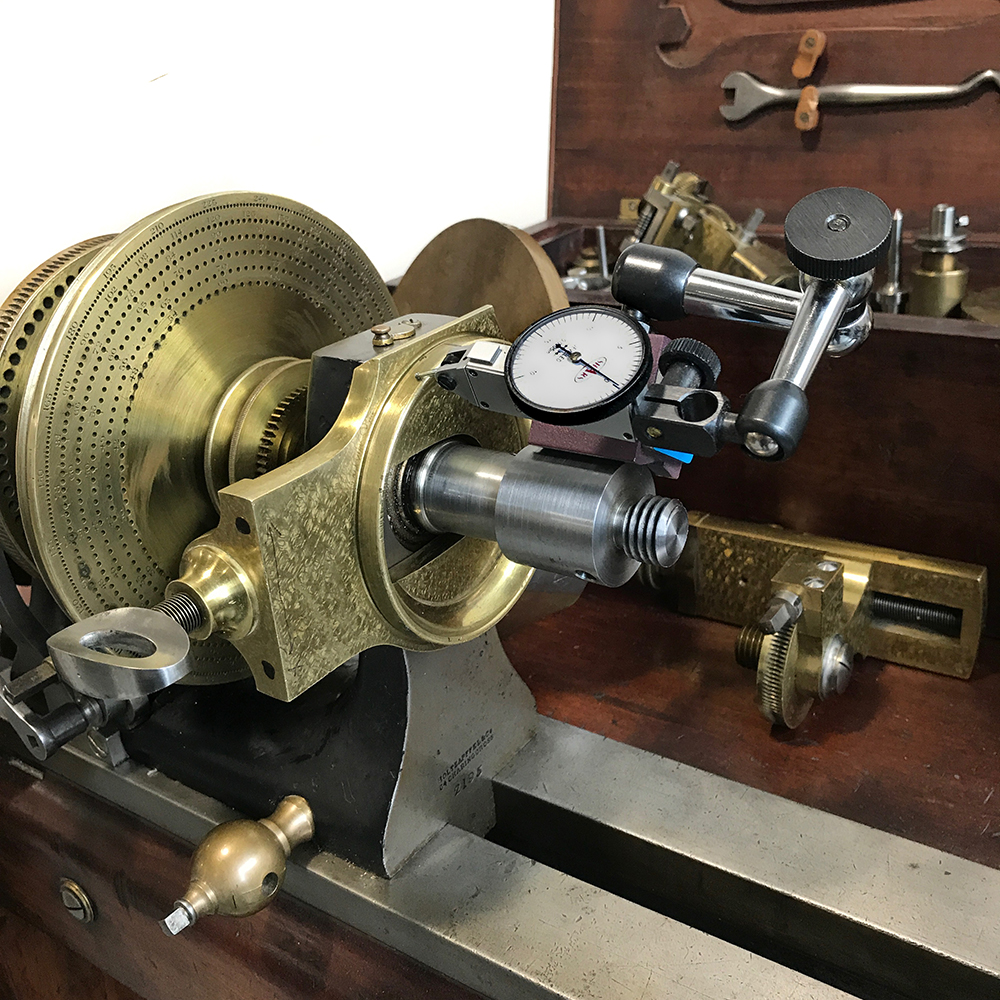

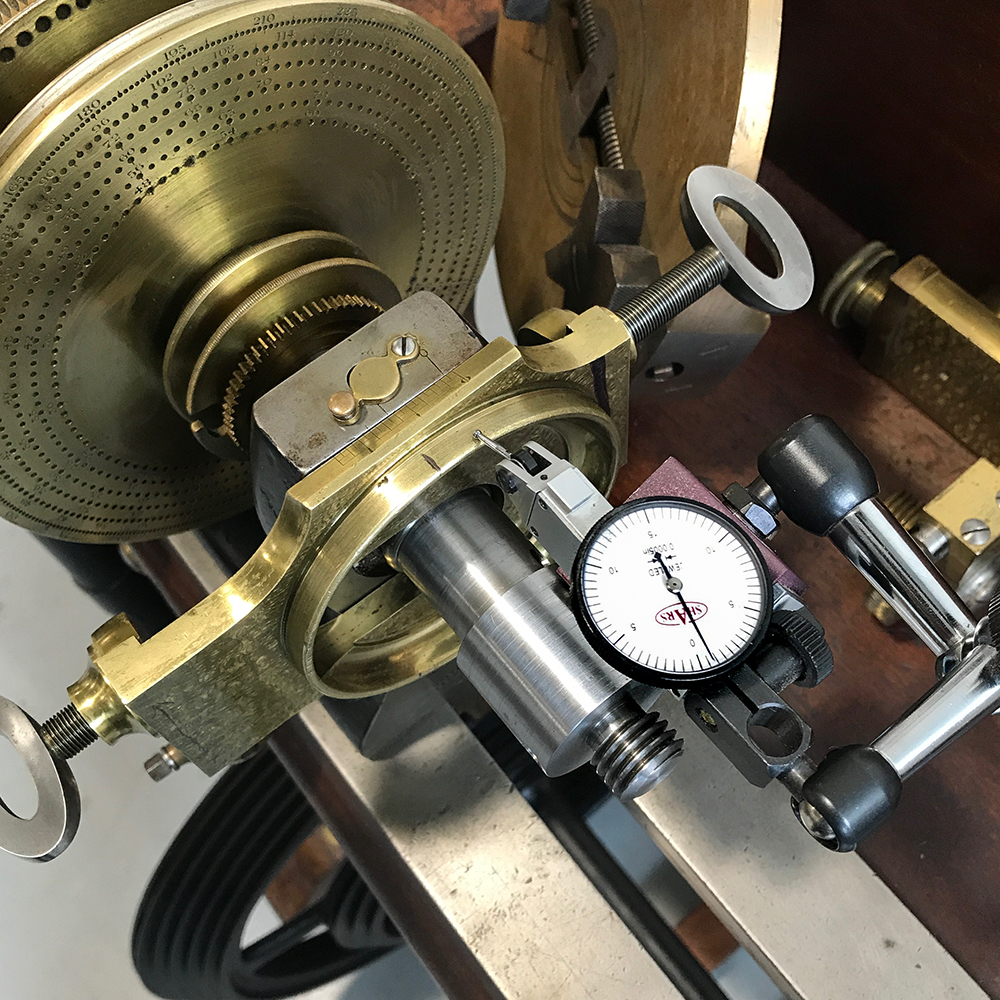

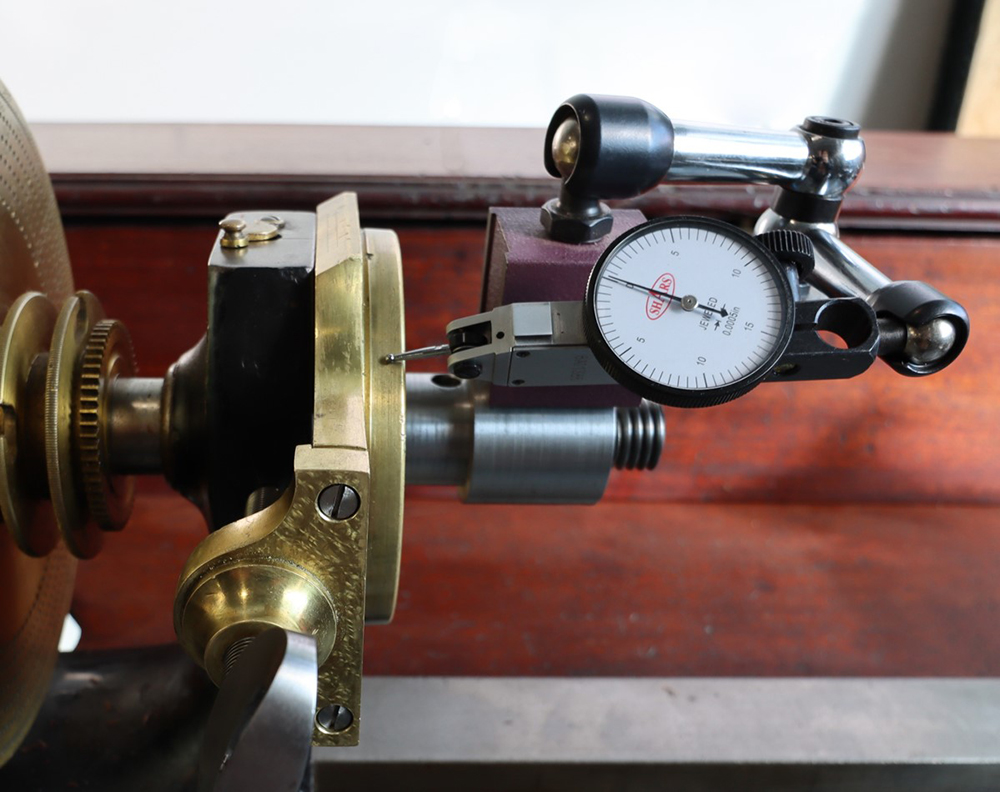

Once the pallets were fitted, the cam ring was installed on the headstock. When setting an oval chuck in trim, the first step is to dial in the cam ring. It was here that the excitement generated from having solved the pallet problem was squelched, as it was immediately obvious that the cam ring sat .012” below center with no adjustment.

Finding the lathe to which this cam ring originally belonged was almost as unlikely as it would be to find the cam ring that originally came with this lathe. So, it was decided that we would modify the one received with the lathe in the least invasive way possible to be able to use it. Remarkably, the “O” point on the cam ring and the line on the headstock lined up. Things were looking up just a bit.

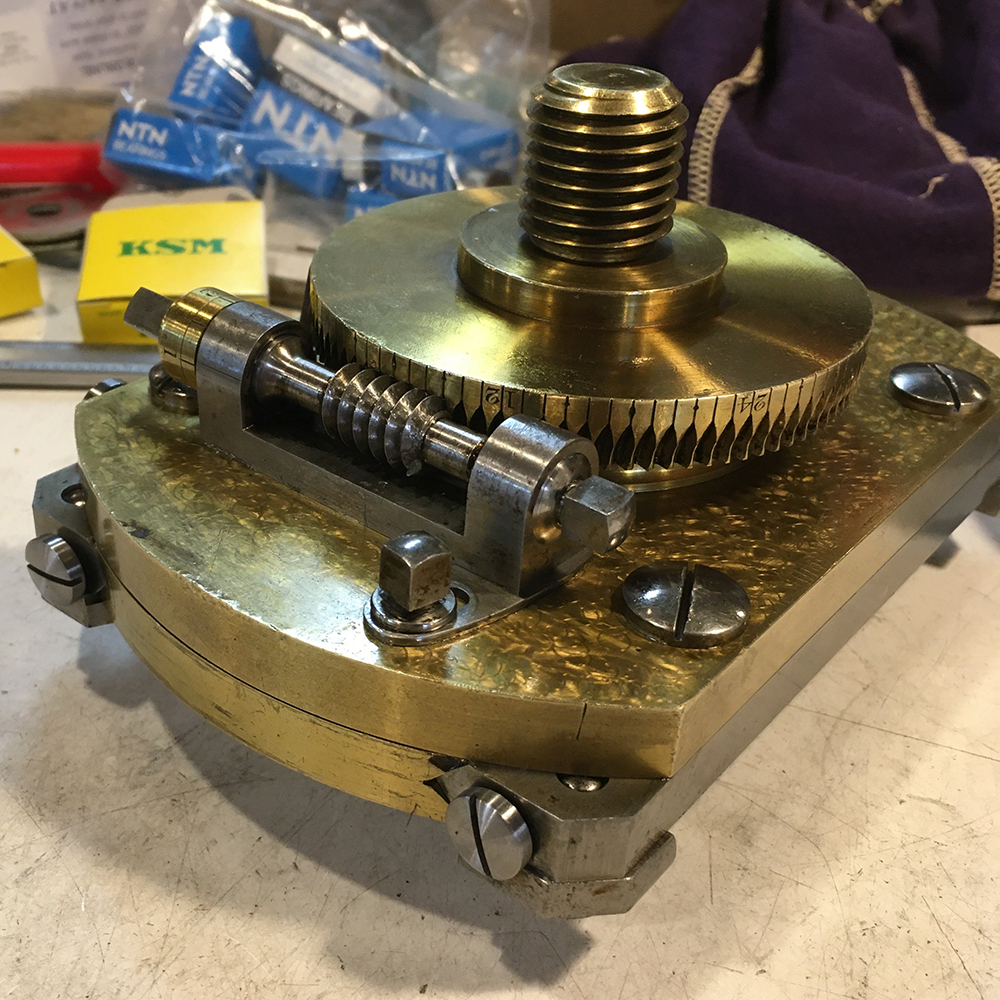

A plan was soon conceived. Separating the ears that carry the adjustment screws from the main body and screwing them back onto the main body would allow the necessary upward adjustment. The cam ring could be put into the milling machine vice and dialed in. Two holes could be drilled in each end and tapped. Then the through holes and counter bores could be offset precisely the .012”, and if the screw heads were made a close match it would repeat to zero. If it didn’t, the holes could be opened up slightly and the cam ring could be adjusted in to zero.

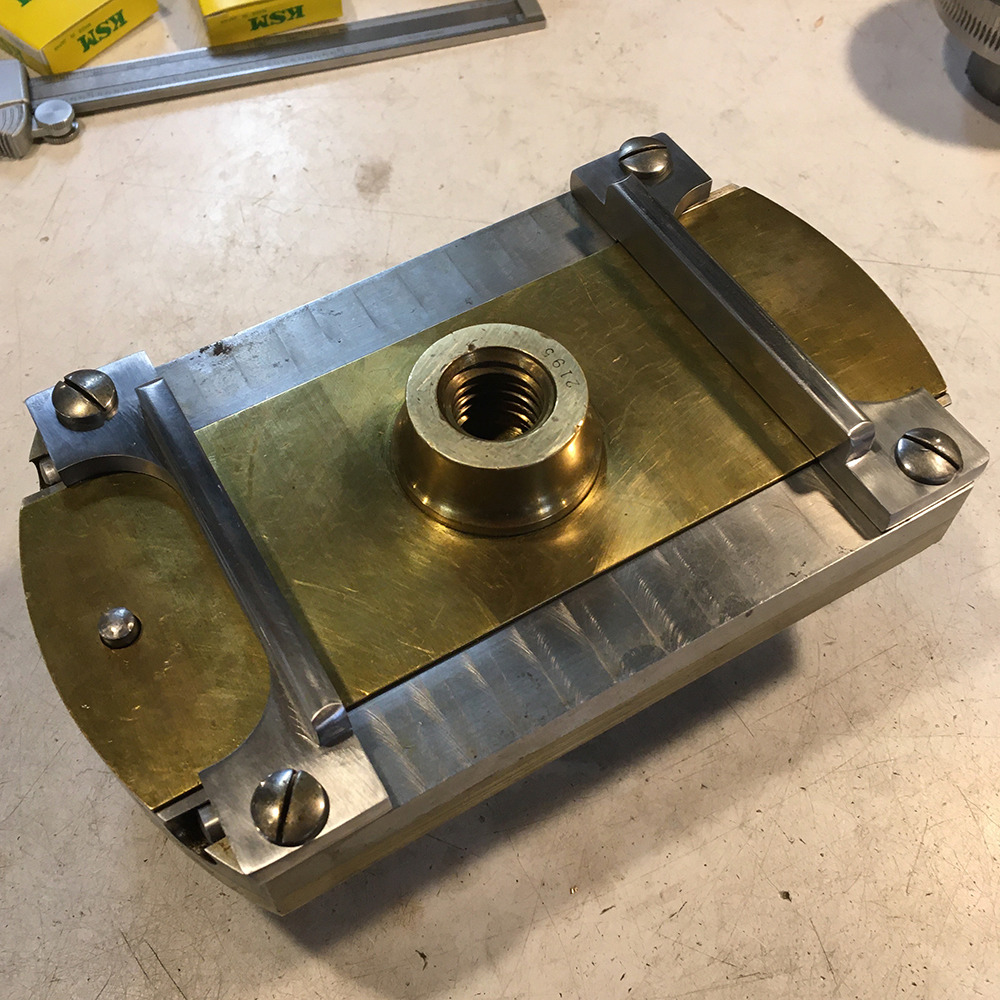

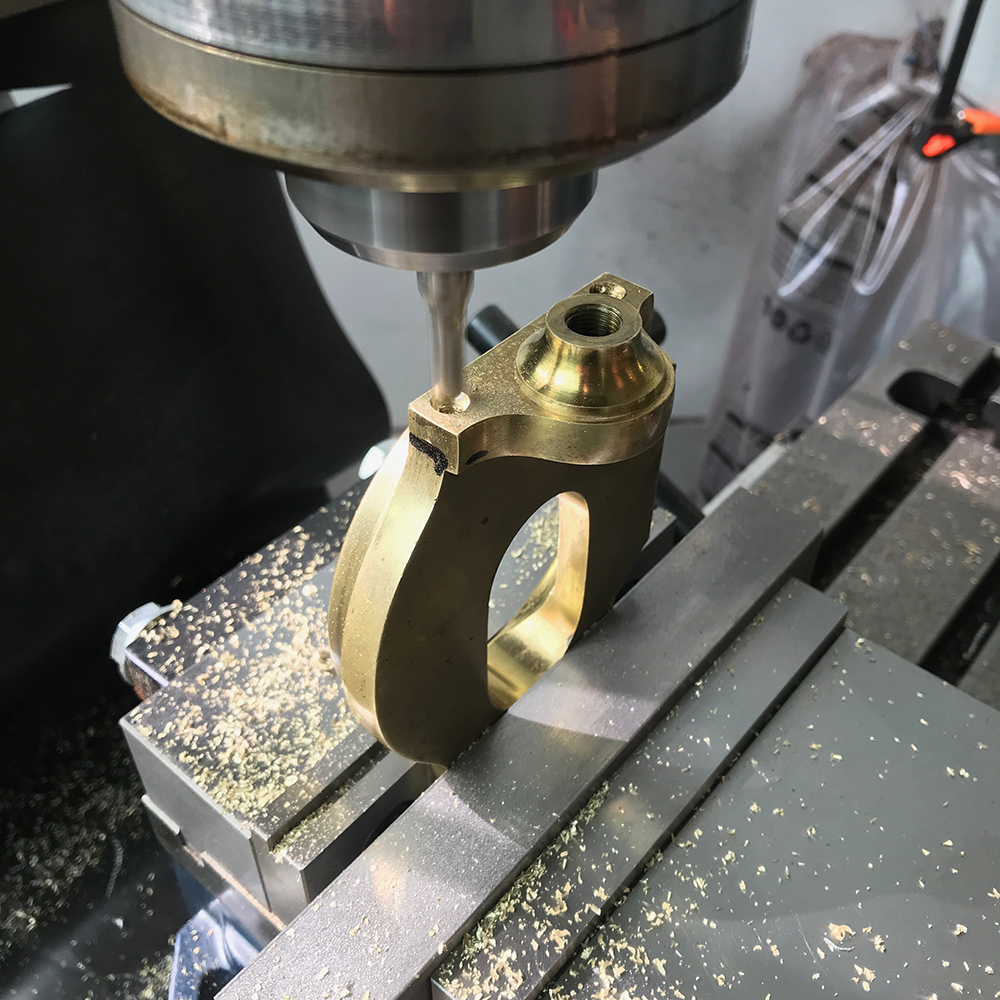

The cam ring was set into the milling machine vice on parallels and then double checked with a machinist level.

The cam ring is drilled and ready to be threaded.

Cam ring after tapping but before the offset counterbore and through hole.

Once the holes were drilled and tapped, the mill table was moved over .012” for the proper offset.

Once the offset counterbores were finished, the outer ears were sawn off with a precision circular jeweler’s saw.

The finished cam ring was installed and once again checked with a dial indicator.

Finished and installed, the oval chuck is ready for service.

In the end the chuck was off center .001” making it the most accurate cam ring of all the Holtzapffel lathes at The Plumier Foundation, and it is now ready service.

Note from the author:

The use of the word “oval” in this blog was intentional. While technically the shape this chuck produces is an “ellipse” I decided to use the word oval because that is what John Jacob Holtzapffel used in Volume V, The Principles and Practice of Ornamental or Complex Turning. Given that No. 2195 is a Holtzapffel lathe, as is the chuck, I used the term he used. One might argue that I have followed him off a precipice, but without having done so what would there be to argue about at this point? Interestingly, John Evans used term “Ellipse Chuck.” Evans was a former employee of Holtzapffel who showed uncanny talent and appears to have left the firm under unhappy terms to start his own manufactory. One has to wonder if John Evans and Charles Holtzapffel had the same argument so many years ago on the shop floor. The biggest argument that comes to my mind over an “oval;” however, is from Jonathan Swift’s Gulliver’s Travels where the “Big Enders” had the age old war with the “Little Enders.”